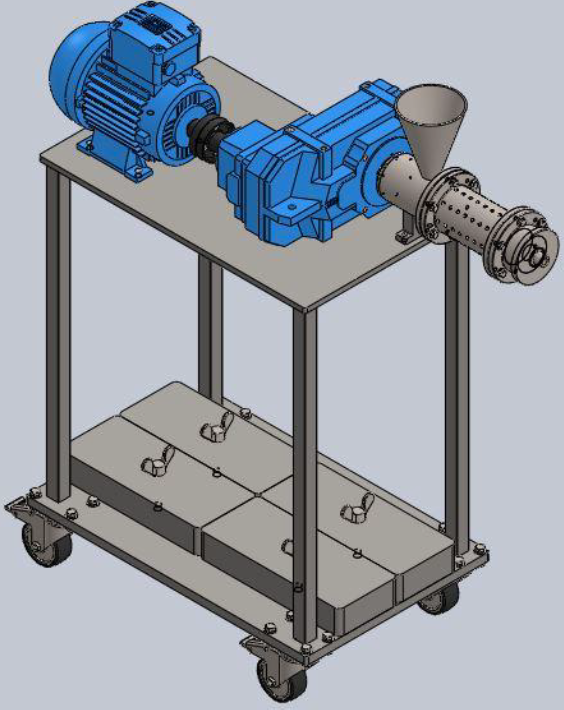

The subject of this paper is conceiving and design development of a cold press oil machine that is powered by conventional electromotor, but has the ability to be manually driven in the event of a power loss or a shortage. In the introductory chapter, there is a brief description of differences between cold and hot pressed oils, and a review of some cold pressed oils obtained from pitiless seeds. Also, there is a classification of oil-manufacturing machines into two major groups, and a description of their operating principle and some basic parts. Furthermore, a market analysis has been conducted alongside a review of some existing machine solutions for cold oil pressing. Few of the basic function of the machine are given through the functional decomposition, while some of the possible designs for those functions are presented in the morphological matrix. Based on those data, four concept machines were taken into consideration. After evaluation, only one of those staged through the final design elaboration. To achieve the required parameters, dimensions for some basic parts were chosen based on calculation, while others are standard parts. In the end, a CAD model and technical documentation were made.

Mario Pandža

2016

Bachelor thesis