Rapid Prototyping

INDUSTRY > Rapid Prototyping

Rapid prototyping

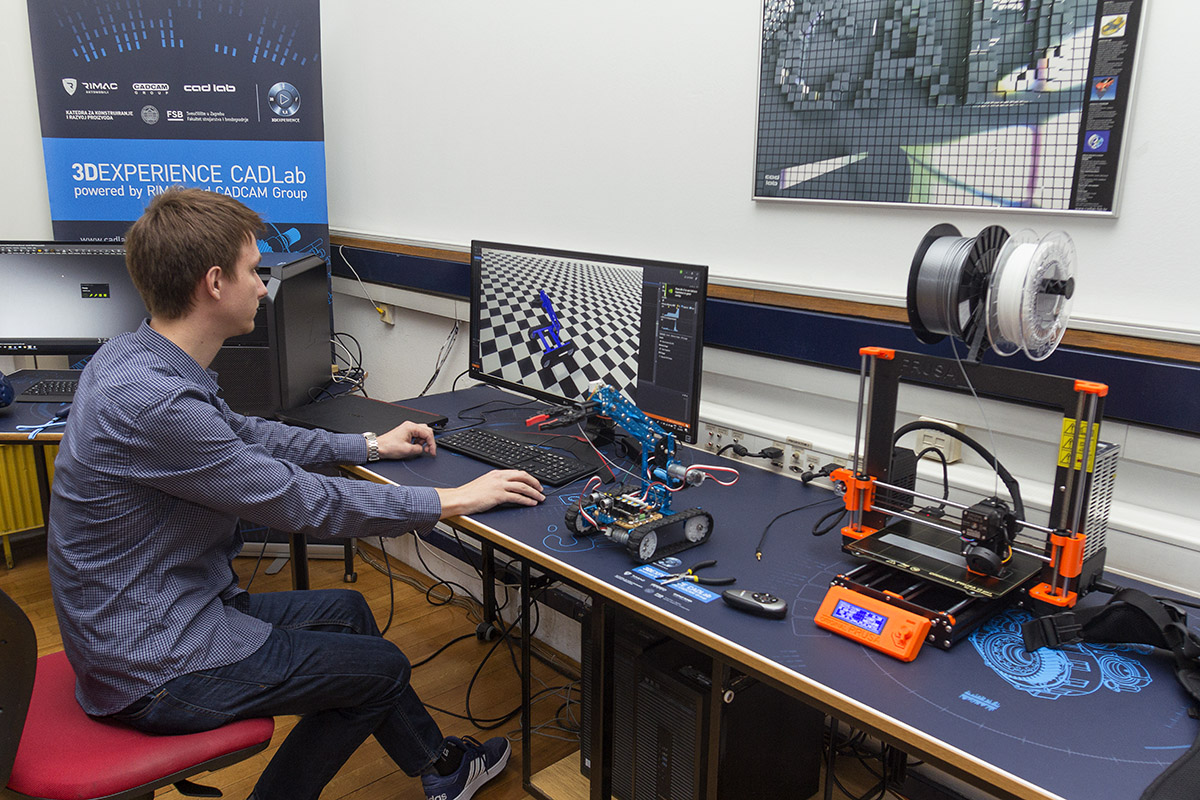

Since 2003, in the CADLab is installed the device for rapid prototyping, Dimension 3D of Stratasys.

Printing technology used by this device is FDM (Fused Decomposition Modeling). ABS (Akrilontril/butadiene/styrene) wire is introduced into the temperature-controlled machine in which the head is heated to a semi-liquid state. The heated material is then extruded through a die in a thin layer. At the same time, the support structure is created by a material that is extruded from the second nozzle. The fundamental advantages of this method are quick and inexpensive prototyping, no negative impact on the environment (no toxic gases), and rapid change of the working material. The downside of this procedure is precision that is the limited by the thickness of the layers (i.e.,. the thickness of the wire material).

The minimum layer thickness is 0.254 mm, a support layer of 0.33 mm. It is especially necessary to emphasise the maximum possible dimensions of the prototype which are: 203 x 203 x 305 mm.

The process of creating prototypes by this device is as follows. Once after in CAD tool a computer model of the product is created, the.STL Record file geometry in a standard format for rapid prototyping should be computed. Such generated STL file is loaded into the program application Catalyst, which will prepare and control the physical prototyping. The Catalyst selects the orientation of prototypes and produces the code to print the prototype made of layers of given thickness. The application can also define the type of support structure. The created software code is then loaded into the rapid prototyoing machine. After producing the product, it is necessary to remove the extra material.