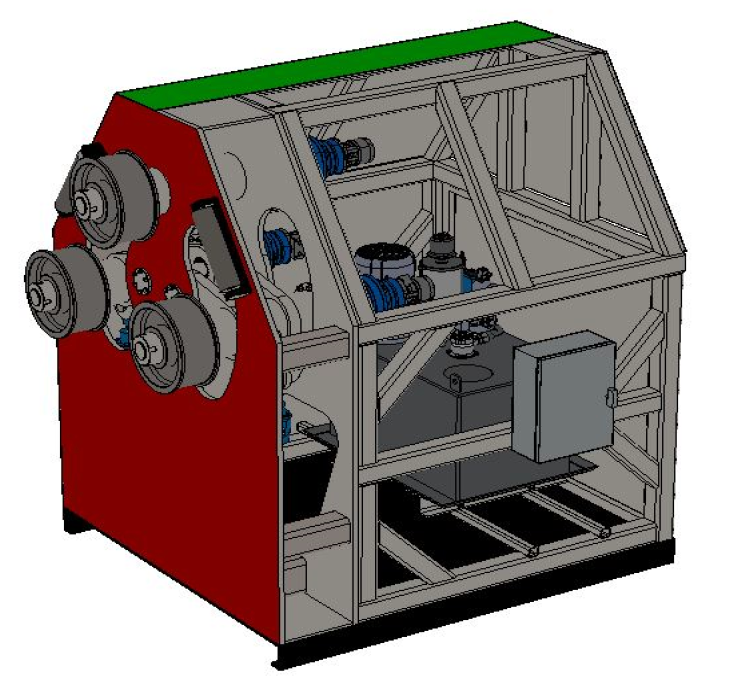

Bending is today one of the most used deformation processes in the world and its application itself is very wide. From the automotive industry, food, aerospace to shipbuilding. By this method, we can bend different materials such as steel, copper, aluminium. It is the most widely applied for the bending of the steel sheets and strips or pipes and profiles. Section bending machines can be used for mass production of bent tubes, such as automotive exhaust pipes, pipe flanges, guide profiles. The primary focus of the work is on bending parts of large dimensions. After conceptualisation, the analysis and selection of the of the standard components were performed, and the 3D model was created in the SolidWorks CAD package. In the first part of the thesis, an analysis of the market is described, and functional decomposition was developed. Emphasis on conceiving was placed on the weight reduction of the machine and its easy maintenance. The second part of the thesis includes the selection and the dimensioning of the critical components of the description of the embodiment principles followed by detail design and conclusion.

Luka Rabuzin

2019

Master thesis