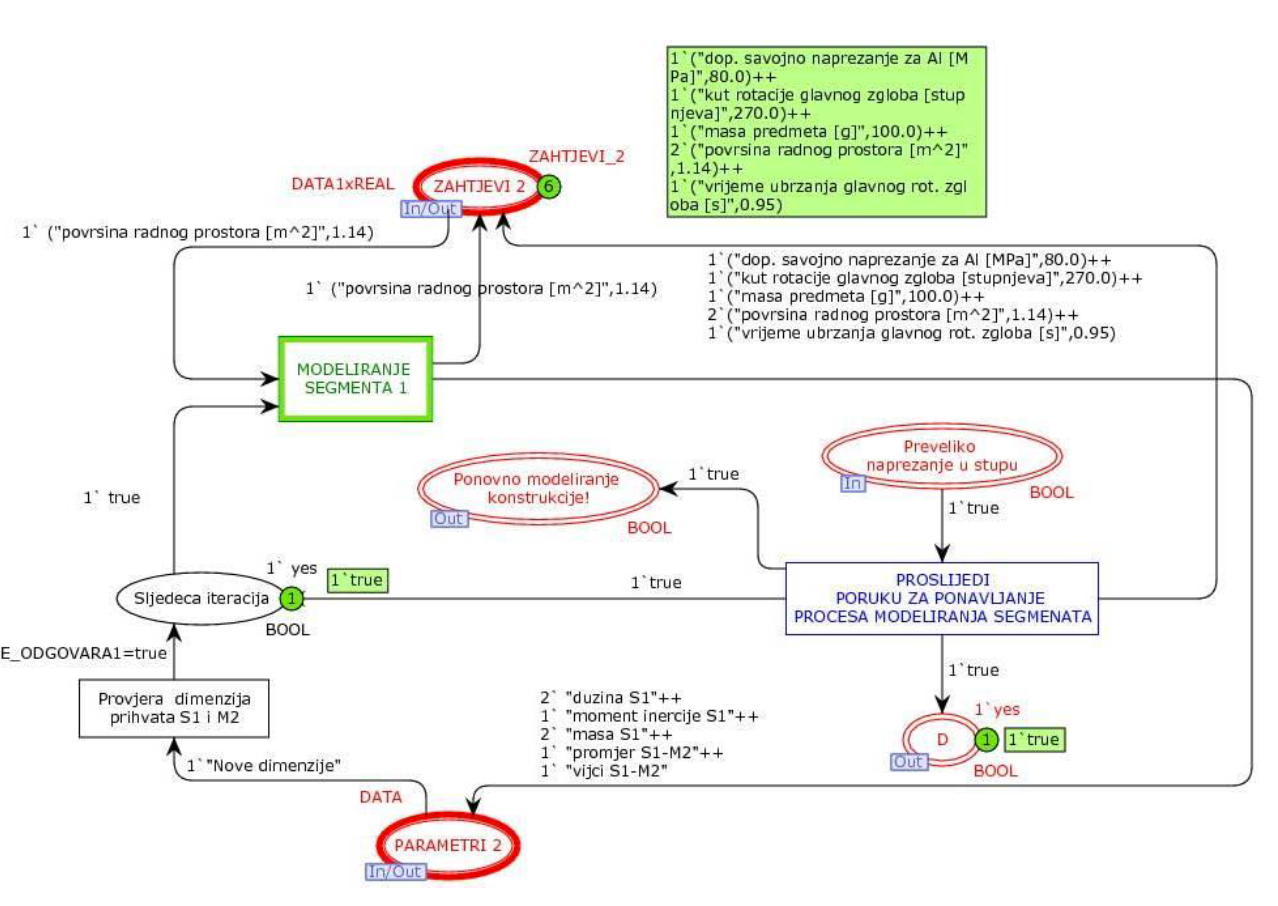

The development of complex products needs to be supported by software so that product information is structured, stored and accessible to the designers who work with those information. These functions were realized with PLM systems, but PLM systems did not support dynamic parameter trails and communication processes in product development. In this paper, it is necessary to create a model of design parameters determination in team work using Petri nets. Prior to analyzing the parameters of the considered constructions, the literature was studied and the most important facts of the current research state were summarized. Processes that have been modeled are the process of design a self-propelled flange cleaner and the process of constructing Scara manipulator. Considered complex products are constructed in team work of two members. The relationships between the parameters are shown in the DSM matrix and a partitioning algorithm has been implemented to see which parameters are sequentially, parallelly and iteratively determined. CPN Tools is selected as a modeling tool for the Petri nets. The basic features of the tool are listed. Models for managing the parameters of the design process of the considered structures with the modeling of the communication process were created. Process simulations can be tracked with the user's choice of transition execution or automatically.

Lorena Vlah

2017

Master thesis