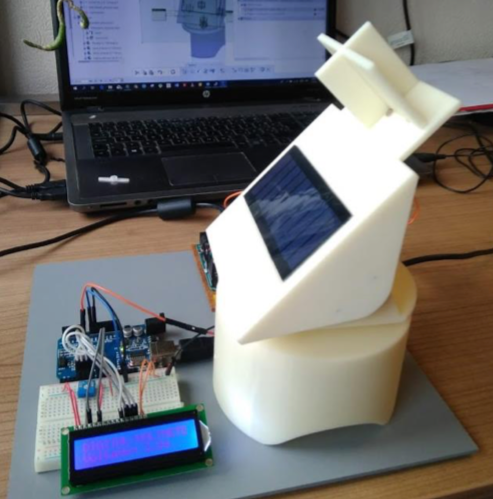

This thesis presents the process of creating a digital twin of a smart product equipped with sensors using the 3DExperience platform. Before the physical realization of a product an introduction to Industry 4.0, its main characteristics and technologies was given along with the description of cyber-physical systems. The concept of digital twin was defined as a digital representation of system's behavior and dynamics which is created during runtime, which is later on used for the optimization of the product's performance. To create a real time virtual representation of a product's behavior, it needs to be equipped with a number of sensors, and the digital environment has to have the ability to enable data collection and transformation so that they can be used for further analyses. Steps for the creation of a digital twin are explained in details with a use case of a solar platform that can adapt to its surrounding in order to maximize its energy production rate. The simplified version of the device was designed, that has all of the main functionalities of a cyber-physical system which uses Arduino microcontroller for control and collection of the product's performance and working conditions data. Arduino connects physical and digital environment through 3DExperience platform using a matching logical unit that translates input signals into a form that enables the motion of a 3D model, which finally represents a virtual twin of a physical product. For further development of this product performance data of the solar panel need to be analyzed together with the data from other sources so that the results can be used for predictive purposes and performance optimization.

Daria Vlah

2018

Master thesis