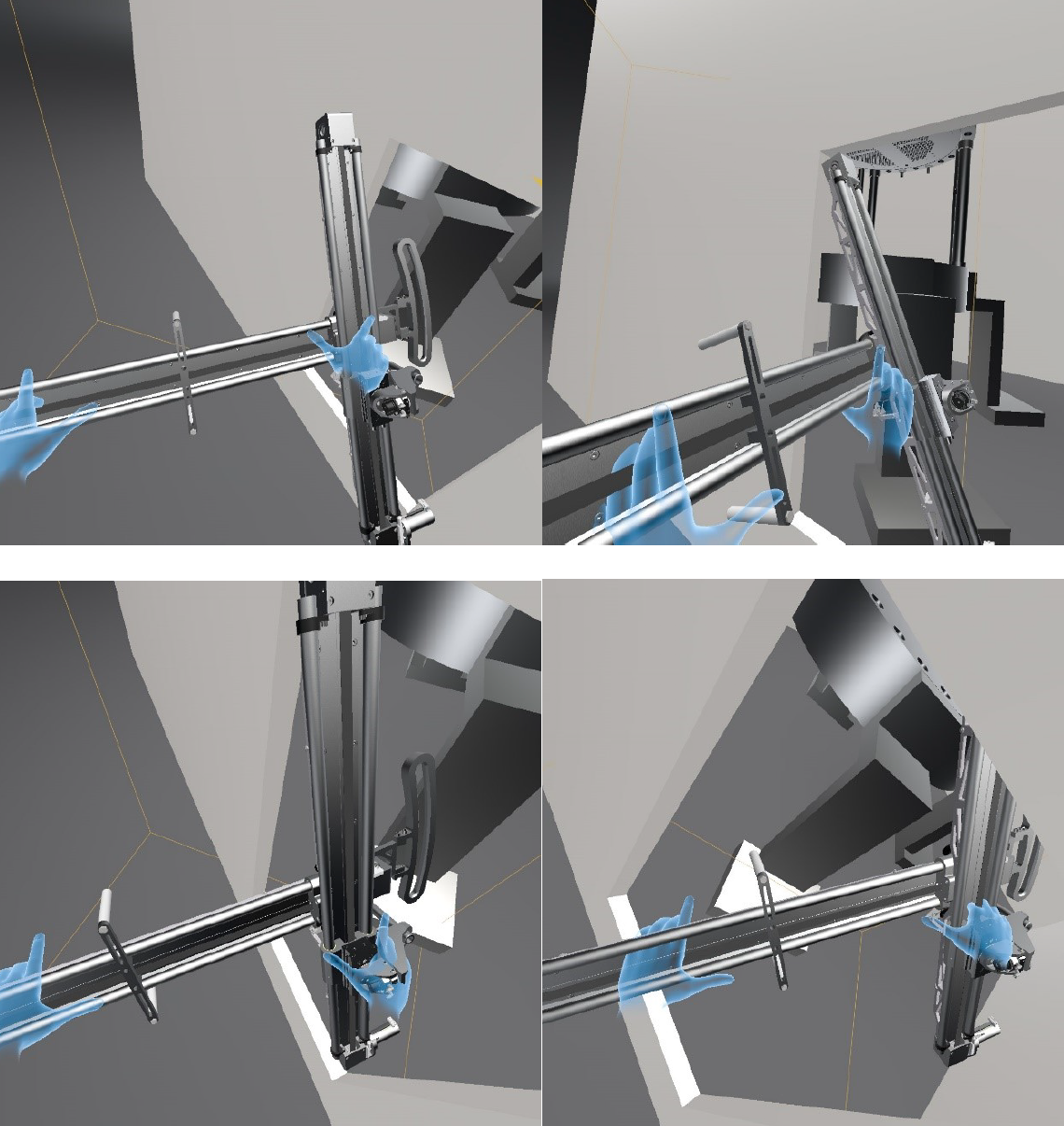

This thesis covers the development of a heat exchanger's tube inspection device. For better understanding of the problem, at the beginning of the thesis a short description of a nuclear power plant is given, along with the explanation of the term „nuclear energy“ and it's transformation inside one of such power plants. Since heat exchanger is an element which transfers heat between closed media circuits of a nuclear power plant, importance and methods of cooling such circuits are explained in detail. There is also given an overview of different types of heat exchangers, where the most common one, shell and tube is described in detail. In the introduction, the term Non Destructive Testing is also explained, along with its importance and application, together with an explanation of most common defects in heat exchanger tubes. After the problem's description, conceptualization phase has started where market research was conducted in terms of patent search, existing products analysis and Inetec's existing products analysis. Market research has been used for defining technical requirements of the device which, along with user needs defined in conversation with Inetec engineers construct house of quality which gives a better overview of resource distribution for the future product development. Functional structure of the product is made and interactions between product's subsystems are explained in detail. Solutions for partial functions are given in the morphological matrix, after which concepts were generated. Concepts were evaluated and selected concept's further development is documented and explained in detail. The selected concept is developed and modelled in Autodesk Inventor 2020 software. The possibility of installation and assembly of the device in heat exchanger's room is examined in the last part of the thesis using virtual reality technology.

Filip Koraca

2020

Bachelor thesis